![]()

Prof. Tang Jie and Prof. Yang Fan of Shanghai Engineering Research Center of Molecular Therapeutics and New Drug Development recently developed a new synthetic processing line of DHEA with an annual production of 100 tons, the first of its kind in China.

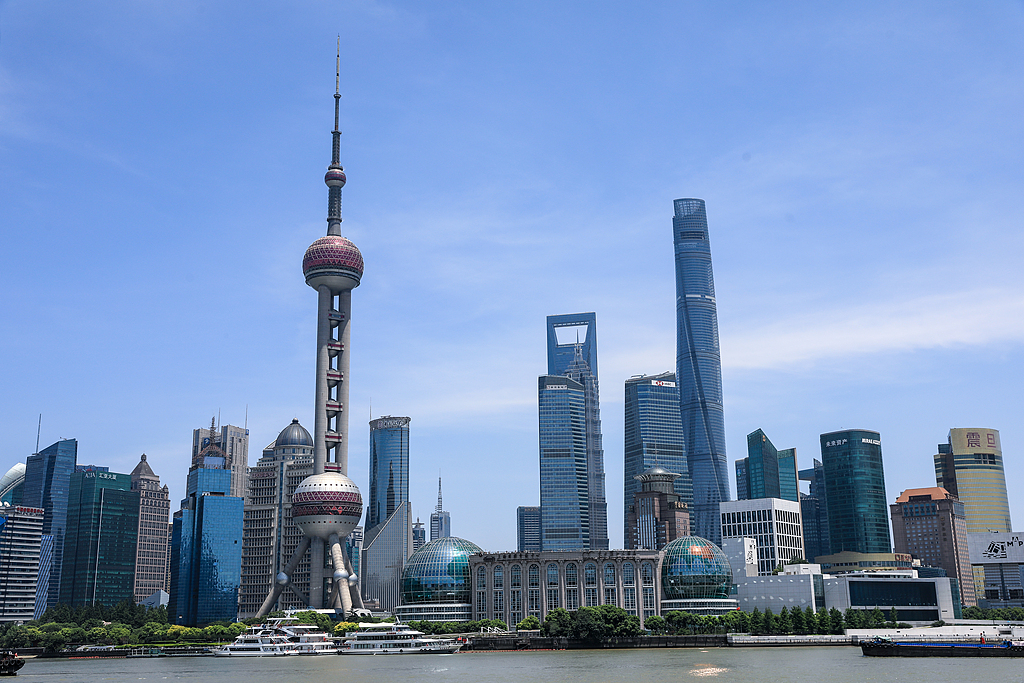

The new synthetic processing line of DHEA with an annual production of 100 tons is put into operation.

As the second categories of drugs after antibiotics, steroid drugs are widely used in the treatment of rheumatoid arthritis, asthma, skin disease; and can also be used for contraception, tocolysis, relieving symptoms of menopausal women, weight loss, etc.. At present, the world production of steroid drug varieties has reached more than 300.

Dehydroepiandrosterone (DHEA), an important endogenous steroid hormone, is a key metabolic intermediate in the biosynthesis of the steroids. Its raw material is heavily dependent on 16-dehydropregnenolone acetate from diosgenins. China is a main country of diosgenin production with the annual output of more than 4000 tons, accounts for around 90% of the global diosgenin production. However, environmental pollution has plagued the industry for years. With the higher requirement of the environmental production in the country, the prices of diosgenins have kept soaring in recent years.

Prof. Tang Jie (Center) checks the processing line with his teamates.

To reduce the cost and pollution of producing DHEA, Prof. Tang Jie and Prof. Yang Fan began to develop a new synthetic processing line of DHEA with a drug company in Zhejiang Province three years ago. According to Tang, the new synthetic process uses bean oil by-products, a cheap material easy to obtain, instead of diosgenins to synthetize DHEA. With the new processing line, the cost of producing DHEA can be only half of that with the original process. What’s more, there will be much less pollution during the synthetic process with bean oil by-products.

With three-year efforts in lab and the factory, Tang and Yang finally developed the new synthetic processing line of DHEA with an annual production of 100 tons successfully in May, and the processing line has been put into operation since July.

Written by: Liu Jinyu