# Hot Search #

On August 14, a research team led by Prof. Wei Zhang from the State Key Laboratory of the School of Chemistry and Molecular Engineering, ECNU, published a groundbreaking study in the world-leading journal Science. In collaboration with Prof. Johannes A. Lercher (Technical University of Munich, Germany) and Prof. Mal-Soon Lee (Pacific Northwest National Laboratory, USA), the team pioneered the world’s first room-temperature catalytic process for upgrading plastic wastes. This distinct one-step method enables the efficient conversion of mixed plastic waste—including particularly challenging yet prevalent plastics such as polyvinyl chloride (PVC) and polyolefins—into fuel-range hydrocarbons. The reaction, catalyzed by chloroaluminate commercial ionic liquids under ambient temperature and pressure, achieves a conversion efficiency exceeding 95% within one hour.

This breakthrough not only overcomes the persistent global challenge of recycling chlorine-contaminated plastics but also provides a transformative solution for mitigating worldwide plastic pollution. ECNU was the lead institution for this work, with Prof. Zhang Wei serving as the first and co-corresponding author.

Prof. Wei Zhang at the State Key Laboratory of School of Chemistry and Molecular Engineering, ECNU

Beyond Traditional Recycling: Addressing the Intractability of Plastic Waste

Plastics have become indispensable for modern social and economic development. Since their industrial production began in the 1950s, their light weight, durability, and low cost have led to widespread adoption across industries such as packaging, construction, electronics, healthcare, and aerospace. As global demand continues to grow, plastic production has surged dramatically, with cumulative output exceeding 10 billion metric tons. Approximately 80% of plastics ultimately ended up as waste, resulting in severe resource depletion and critical environmental pollution.

Against this backdrop, advanced plastic “upcycling” technologies have emerged. By leveraging novel chemical pathways, these methods overcome the limitations of traditional recycling. They not only convert discarded plastics into high-value products—offering one of the most promising solutions for the circular economy—but also alleviate resource scarcity, thereby ushering in a new era of “waste-to-wealth” conversion.

The Environmental Pollution from Plastic Waste Landfilling and Incineration

Closing the Loop: Upcycling Plastic Waste into Fuels

A Breakthrough in Low-Temperature, One-Step Catalytic Valorization of Waste

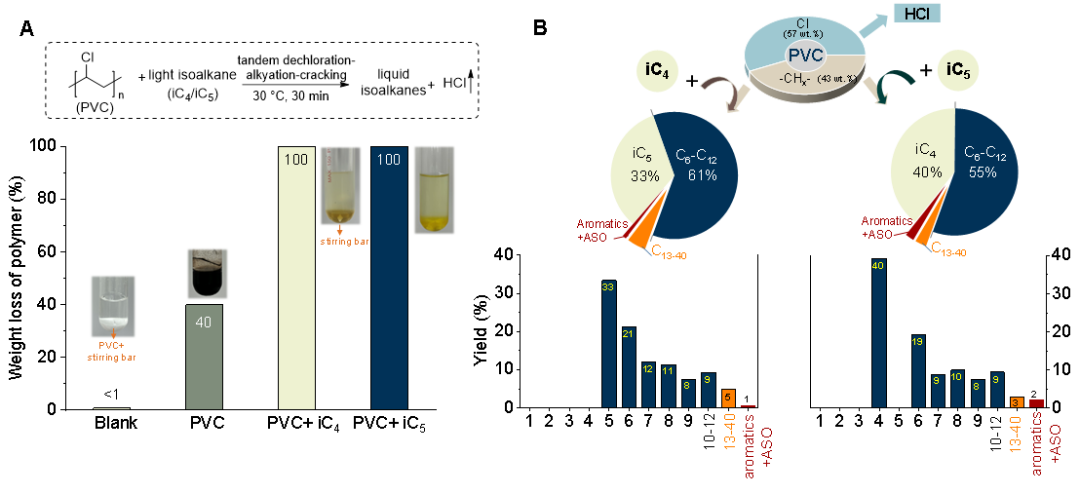

The chemical upcycling of PVC-containing mixed plastic waste remains a significant technical challenge. Conventional processing typically requires a two-step “dechlorination–cracking” approach: chlorine is first removed using a dechlorinating agent, followed by high-temperature cracking to produce fuels or chemicals. However, this approach is hampered by several critical drawbacks, including high energy consumption, substantial operational costs, and incomplete dechlorination leading to catalyst poisoning. Furthermore, it often results in low oil yields and excessive chlorine residues in the products. These bottlenecks severely hinder the efficient resource utilization of PVC-containing waste, presenting a major obstacle to achieving "carbon peaking" and "carbon neutrality" goals.

To address this challenge, Zhang’s team drew key inspiration from petroleum refining processes, proposing an innovative strategy for the low-temperature catalytic upcycling of plastic wastes. Conventional petroleum refining involves two core steps: catalytic cracking of heavy oils into lighter fractions at elevated temperatures, followed by low-temperature alkylation to upgrade fuel quality. The team ingeniously integrated these two steps to establish a novel "catalytic dechlorination-cracking-alkylation" coupling process, enabling efficient one-step conversion at low temperatures.

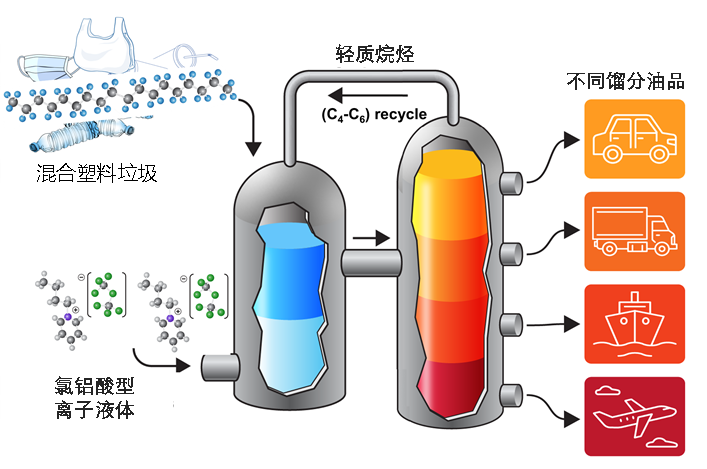

Conversion of PVC Plastic Waste into High-Quality Fuel-Range Hydrocarbons at Room Temperature

This technology achieves three major innovations: it enables conversion under room temperature and ambient pressure, reducing energy consumption by over 70%; integrates dechlorination, cracking, and alkylation into a single-stage step; and creatively employs petrochemical by-products (isobutane) as the co-reactant into a "waste-to-treat-waste" approach. Together, these advances unlock efficient, value-added utilization of plastic waste.

Experimental results showed that this process achieves the one-step conversion of mixed waste plastics into high-grade gasoline, achieving a carbon balance exceeding 95%. This "molecular refining" strategy significantly improves the economic viability of plastic recycling while establishing a complete circular resource utilization chain. Consequently, it presents a practical and scalable solution to the global challenge of plastic pollution.

Strategic Industrial Layout: A Novel Approach to Controlling Plastic Pollution

From a process design perspective, the team prioritized industrial feasibility and selected an ionic liquid catalyst. This choice was driven by the catalyst's low cost, high activity, low corrosivity, and proven operational safety and reliability, which have been previously demonstrated in industrial alkylation units operated by Chevron (USA) and CNPC (China). The technology allows the near-complete conversion of mixed plastic waste into chlorine-free, high-quality fuel.

In contrast to conventional high-temperature cracking, the process operates at room temperature, enhancing its safety. It generates no toxic by-products and effectively eliminates chlorine pollution. The chlorine from PVC is converted into recoverable hydrogen chloride, which can be dissolved in water to form non-toxic hydrochloric acid—a substance that is naturally a major component of human gastric acid. This approach simultaneously achieves efficient resource utilization and ensures environmental safety.

Conceptual Process Diagram for the Catalytic Upcycling of Post-Consumer Plastic Waste into Liquid Fuels

It is worth noting that in 2023, Prof. Zhang, as first and corresponding author, published findings in Science demonstrating the low-temperature conversion of polyolefin wastes. The present study represents a significant advancement beyond this earlier work by successfully incorporating the more challenging PVC wastes and reducing the required reaction temperature to ambient conditions. This breakthrough enables the green and efficient recycling of over 60% of common plastic waste streams. From an industrial application perspective, the technology demonstrates strong compatibility with existing petroleum refining infrastructure. Its low energy requirements, operational simplicity, and high conversion efficiency make it particularly suitable for implementation within current petrochemical production facilities.

Room-Temperature Upcycling of Chlorinated Polyolefin Wastes into Fuels and HCl, Compatible with Petrochemical Refining Processes

Returning to the Alma Mater to Pursue Dreams Together

Prof. Zhang acknowledges that this scientific achievement was made possible by the flourishing research environment and robust support from the scientific platforms and resources at ECNU. In 2012, he began his master’s degree in the Green Chemistry Laboratory at ECNU under the supervision of Prof. Ming-yuan He and Prof. Hai-hong Wu. This foundational experience equipped him with deep expertise in catalysis and a strong grounding in the principles of Green Carbon Science. Following a recommendation from Prof. He, Zhang earned his Ph.D. in 2019 at the University of Amsterdam, the Netherlands. From 2020 to 2023, he worked as a postdoctoral researcher and senior scientist with Prof. Johannes A. Lercher at the Technical University of Munich, Germany. After that, he joined the Institute of Integrated Catalysis at the Pacific Northwest National Laboratory, USA.

With deep affection for his alma mater, Zhang chose to return to ECNU. With the strong support of Prof. He and the university leadership, he quickly established his own research team and embarked on a new scientific journey. “It is precisely thanks to ECNU’s exceptional research environment that we can integrate resources from both within and beyond the university and collaborate with world-class institutions,” He stated: “This synergy not only enables original breakthroughs in fundamental research but also promotes the industrialization of our findings, allowing us to achieve continuous innovation in the fields of energy and environment.”

Reflecting on his career, he added: “From being a master student to independently leading my own team, ECNU has witnessed every key milestone in my scientific journey. It has provided the most robust platform and the most fertile soil for realizing my academic aspirations.”

In future, the team will leverage ECNU’s first-class research platforms to advance the industrialization of green catalytic technologies. A key strategy involves forging pilot-scale collaborations with leading petrochemical enterprises to bridge the gap between laboratory discovery and commercial application. Furthermore, the team is pioneering the integration of artificial intelligence to design more efficient catalytic systems and elucidate complex reaction mechanisms at the atomic level. Finally, they plan to promote the global dissemination of these sustainable technologies through ECNU's extensive international cooperation platforms.

Link: https://www.science.org/doi/10.1126/science.ade7485

Author: Xu Xincheng

Copy editor: Philip Nash

Editor: Wicky